The aim of this paper was to study the effectiveness of N2/Ar gas ratio on the mechanical and

tribological properties of Ti-Zr-N films coated on (AISI 304 stainless steel) substrate. The thin films

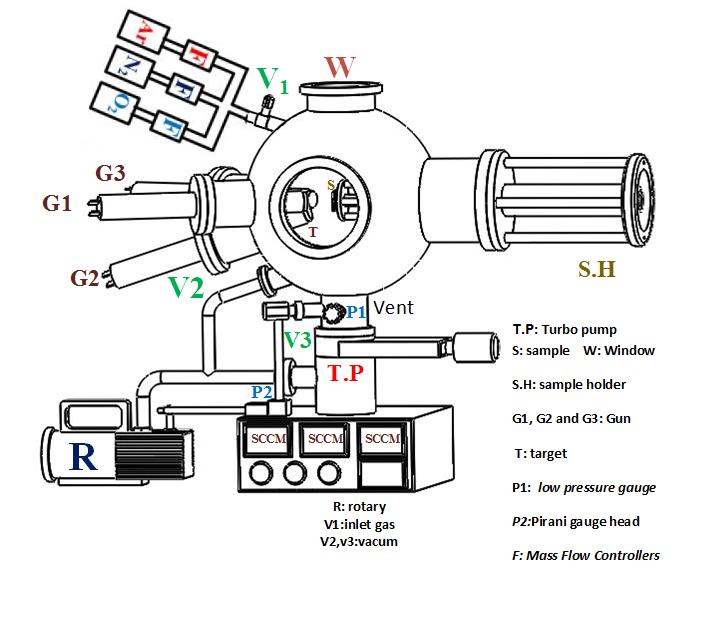

were produced at 150 W pulsed magnetron sputtering (PMS) technique operated for 90 min. The

structure and tribo-mechanical properties of the Ti-Zr-N coatings were investigated at different N2 /Ar

gas pressure ratio. X-ray diffraction (XRD), microhardness, surface roughness, wear and friction,

corrosion performance and surface energy were investigated. The analysis of X-ray diffraction (XRD)

indicated a formation of solid solution phase of (Ti-Zr)N with (FCC) structure and a chemical

compound phase of TiN. The solid solution phase (Ti-Zr)N has the orientation (111). The

microhardness of the thin films has high values compared to associated value of (AISI 304 stainless

steel) substrate; up to 4-folds. Furthermore, the wear performance was improved from 73.06 mm3

/m

for AISI substrate to 5.01 mm3

/m after depositing Ti-Zr-N. The coefficient of friction was decreased

from nearly 0.69 for the austenitic substrate to nearly 0.12 after coating with Ti-Zr-N. Over and above,

the corrosion resistance substantially improved (factor of 1000 times) after the coating