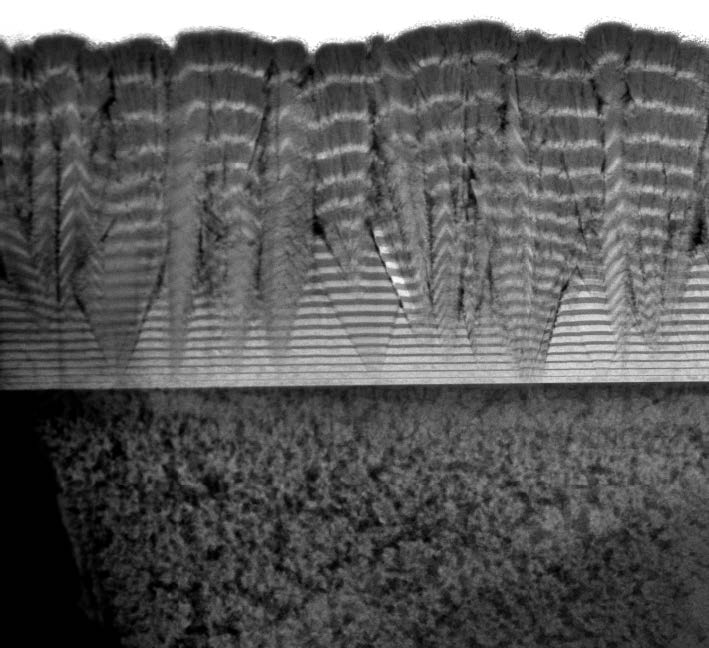

Bulk metastable phases can be stabilized during thin-film growth by employing substrates with similar crystal structure and lattice parameter, albeit over a thickness range limited by coherency-strain relaxation. Expanding that strategy, growth of superlattices comprising one stable and another metastable compound with similar crystal structure and lattice parameters are known to yield epitaxial stabilization over a few nanometers of thickness. In this work, the high-pressure rocksalt (B1) phase of Al0.72Sc0.28N was stabilized epitaxially in a multilayer with TiN with thicknesses of up to 26 nm. In order to investigate the microstructural changes leading to the phase transformation of the metastable B1 phase to its wurtzite allomorph, we demonstrate a design based on a multilayer architecture with systematically varying thicknesses of the metastable compound within a constant-thickness lattice of stable metallic TiN with the cubic rocksalt structure. The multilayer films show an increasing hardness and elastic modulus for decreasing period thickness, in correspondence with both coherency-strain and Koehler hardening. The phase transition is accompanied by an increase of lattice strain with increasing multilayer periods, and resulting ultimately in coherency-strain relaxation upon phase transformation. Further, we show that the phase transformation is mediated by voids decorating the {130} planes that separate regions of different growth rates and act as additional growth fronts for wurtzite growth during the phase transformation. The TiN/(Al,Sc)N interfaces themselves remain atomically sharp and smooth until the interface structure roughens along with the epitaxial rocksalt to wurtzite transition of (Al,Sc)N. These results show the strong influence of the voids on controlling the target thickness of epitaxially stabilized thin-film growth to the range relevant for applications, such as coatings, plasmonic materials, and electronic device technology, where the mechanical integrity of the material is critical.